The path PET takes to reach you

25/10/2022PET is one of the most present types of plastics in our lives. Very innovative for its lightness and resistance, PET has provided a real revolution in the industries it serves, such as beverages, for example.

To name a few benefits, we have the logistics chain which is greatly benefited by PET’s resistance and lightness, the product’s very high protection capacity, (PET has excellent chemical resistance, and strong barriers against gases and odors), and the low production cost, which makes the product’s final price more accessible.

But do you know the path PET takes to reach our homes?

Valgroup PET is produced with the best raw materials and equipment on the market, undergoing a thorough technological process to meet the most rigorous quality criteria.

The PET production process

The first stage in the process is the production of PET resin.

![]()

This resin is injected into preforms

![]()

The preform then goes through a blowing process that gives it its final bottle shape.

![]()

After blowing, the bottle receives a label and cap, is filled with the product, and ready for transportation to the shelves.

![]()

PET bottle recycling

Another fundamental advantage of PET is that its recycled version can be used in contact with food since 2008, an advance of which Valgroup is a pioneer, having been the first plastic processing company to obtain ANVISA’s approval for such.

This has made the PET recycling chain valued, which is why it has the highest recycling rates among plastics.

PET recycled bottles are already available on the market, for example, PET packaging partially or even fully composed of post-consumer recycled PET resin (PET PCR), as is the case of the Natural One bottle, the best-selling natural juice brand in the category, produced with 100% PET PCR resin and developed in partnership with Valgroup, which won the Great Packaging Cases award in 2022.

Learn more about Valgroup’s history with PET on our website and social networks.

Stay tuned in to the world of plastic technology, innovation and sustainability

Valgroup launches solutions focused on end-of-line automation

Continue reading

Discover Valgroup’s BOPP solution for In-Mold Label

Continue reading

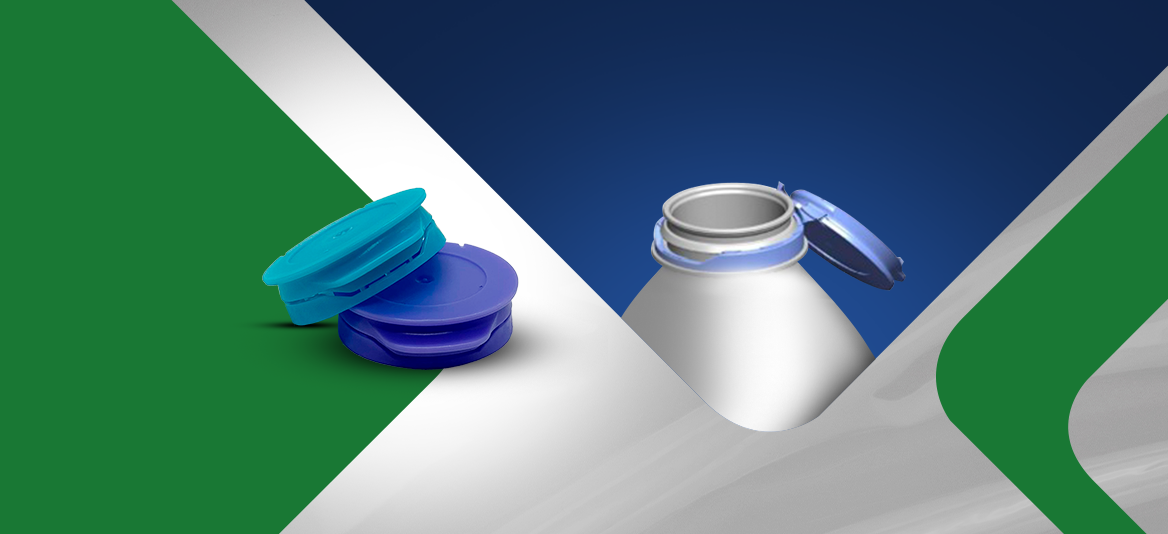

Innovation and Sustainability: Introducing Valgroup's new cap 'Snap-on Flip Top'

Continue reading

Valgroup Run 2024: Running and Solidarity with the new Valgroup Run Kids

Continue reading

The importance of shelf life for food safety and waste reduction

Continue reading

Valgroup Sustainable Innovations: Sustainability Commitment

Continue reading

Valgroup is the new supplier of Tissue packaging for Bracell

Continue reading

Comerc Energia inaugurates São João do Paracatu photovoltaic complex, and Valgroup expands its consumption of renewable power, reinforcing the commitment to sustainability

Continue reading

Valgroup launches a new Business Unit in the market dedicated to Digital Printing

Continue reading