Valgroup Packaging for the Tissue Market

30/03/2022Valgroup also has complete solutions for the Tissue market. These are primary, secondary and tertiary packages that guarantee logistical safety, highlight the product on the shelf, as well as make the packaging process easier and more efficient, reducing waste and excessive use of film.

Among these solutions are those produced with MDO (Machine Direction Orientation) technology. Designed to meet customer needs as well as the planet’s needs when it comes to reducing the use of plastic in its packaging, MDO is a more sustainable primary packaging, since it reduces film thickness by up to 40%, while improving properties such as tear and perforation resistance. It also gives it more shine, transparency and the ability to count on up to 40% post-consumer recycled resin in its composition.

MDO Characteristics

Less plastic, greater resistance, brightness, performance, transparency, and sustainability.

Thickness: 30 to 45 microns

Ideal packaging for 4 to 24 rolls

Gloss: 55%.

Haze: 15%.

PCR percentage: up to 40%

Other Valgroup solutions for the Tissue market are Stretch PCR for arm rotary machine application, and PCR Bales for bales of any size, and with the same protection as bales made from virgin resin.

Specialized Service

Valgroup offers specialized assistance to its Tissue market customers, carrying out process parameter adjustments to extract the best performance from the product and its production lines and performing preventive supervision to detect points of improvement in the film in order to increase productivity and reduce costs for the customer.

In addition, we have partnerships with equipment manufacturers for the assembly of new production lines. The technical assistants have the expertise to support the installation of these new production lines for customers, aiming for the best adaptability between the machinery and the film, such as plant start-up, and advisory experience to improve film performance in the largest transformers. Together, it is possible to define the best technical solution for new lines.

In this way, Valgroup provides high quality solutions and specialized support and service in order to guarantee the best equipment performance, process optimization, and customer satisfaction.

Load Test Center

Valgroup’s LTC is the largest transportation simulation Lab in the Americas. Here we perform the diagnosis of the palletized load wrapping stage for our clients, develop an optimized application and implement it from tests of real situations in the logistics chain. This way, we offer a customized solution that ensures greater efficiency in the packaging process. A solution that uses only the necessary amount of film to ensure the product’s safety during transportation, which reduces costs and promoting sustainability.

Stay tuned in to the world of plastic technology, innovation and sustainability

Valgroup launches solutions focused on end-of-line automation

Continue reading

Discover Valgroup’s BOPP solution for In-Mold Label

Continue reading

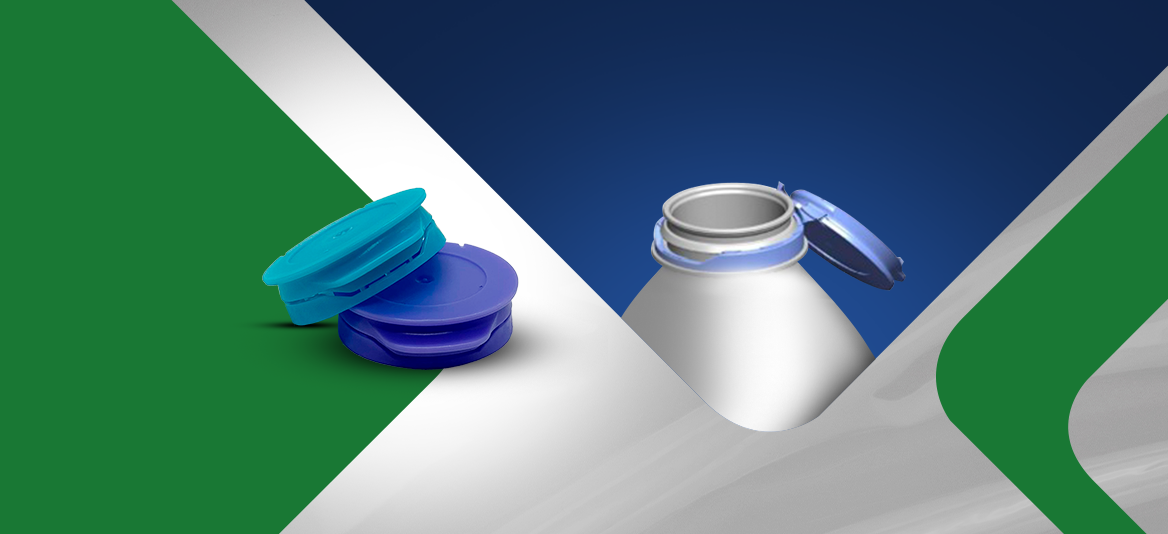

Innovation and Sustainability: Introducing Valgroup's new cap 'Snap-on Flip Top'

Continue reading

Valgroup Run 2024: Running and Solidarity with the new Valgroup Run Kids

Continue reading

The importance of shelf life for food safety and waste reduction

Continue reading

Valgroup Sustainable Innovations: Sustainability Commitment

Continue reading

Valgroup is the new supplier of Tissue packaging for Bracell

Continue reading

Comerc Energia inaugurates São João do Paracatu photovoltaic complex, and Valgroup expands its consumption of renewable power, reinforcing the commitment to sustainability

Continue reading

Valgroup launches a new Business Unit in the market dedicated to Digital Printing

Continue reading