Valgroup technology reduces thickness of the packaging film by up to 40%

11/05/2023MDO technology, in addition to being sustainable, improves properties such as resistance, brightness and transparency.

Designed to meet the needs of the clients (and the planet), Valgroup has in its portfolio a more sustainable primary packaging for the tissue market: the MDO (Machine Direction Orientation) technology, with which it is possible to reduce film thickness by 37.5%. In addition, there are improvements to packaging properties such as tear and puncture resistance, more brightness and transparency.

Currently, a package of toilet paper with 12 rolls contains about 18.25g of plastic in its composition. Using Valgroup MDO technology, the weight of this package could be reduced to just 10g on average, meaning more protection using less material.

Valgroup has been developing and producing flexible plastic packaging for more than 45 years and is constantly looking for innovations to meet the needs of its customers.

Stay tuned in to the world of plastic technology, innovation and sustainability

Valgroup launches solutions focused on end-of-line automation

Continue reading

Discover Valgroup’s BOPP solution for In-Mold Label

Continue reading

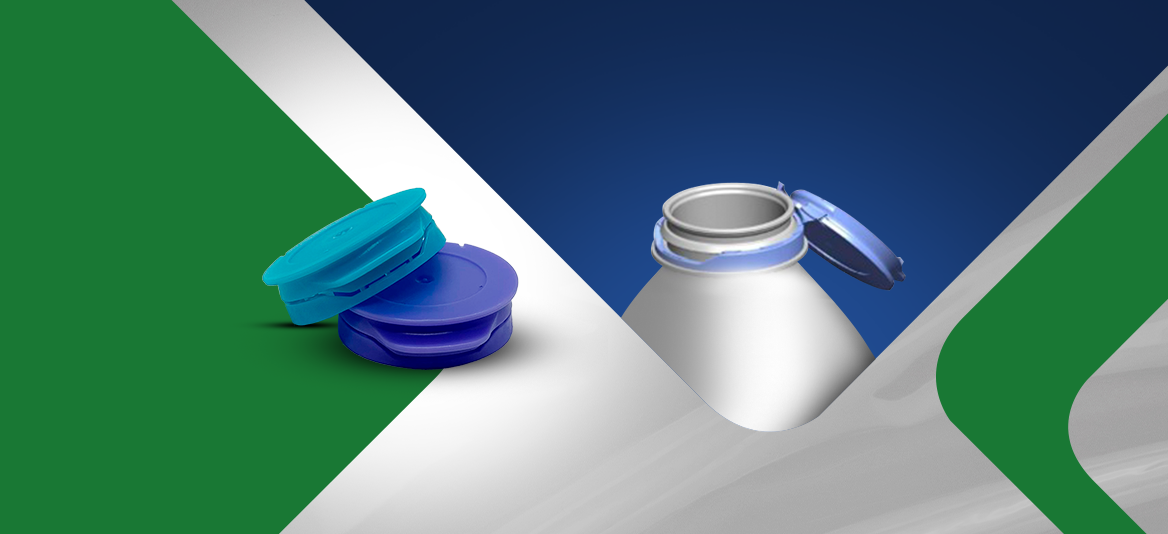

Innovation and Sustainability: Introducing Valgroup's new cap 'Snap-on Flip Top'

Continue reading

Valgroup Run 2024: Running and Solidarity with the new Valgroup Run Kids

Continue reading

The importance of shelf life for food safety and waste reduction

Continue reading

Valgroup Sustainable Innovations: Sustainability Commitment

Continue reading

Valgroup is the new supplier of Tissue packaging for Bracell

Continue reading

Comerc Energia inaugurates São João do Paracatu photovoltaic complex, and Valgroup expands its consumption of renewable power, reinforcing the commitment to sustainability

Continue reading

Valgroup launches a new Business Unit in the market dedicated to Digital Printing

Continue reading