SEARCH

Find the ideal solution for your business

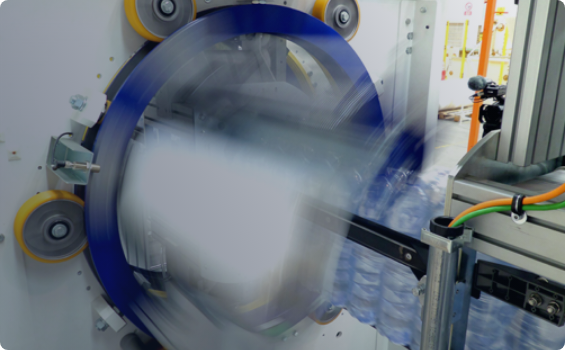

While you browse, we've already recycled:

0

kg of plastic

Calculation made considering the value of 3.5 billion PET bottles removed from the environment annually, divided by one year, including the number of days, hours, minutes, and seconds. These definitions allow us to conclude that one day can be converted into a total of 86,400 seconds. Based on this, along with the user's browsing time, the result is displayed in the website's calculator.