Discover Valgroup’s BOPP solution for In-Mold Label

20/08/2024One of the fastest-growing packaging solutions in the world is the In-Mold Label (IML). This involves inserting the label inside the mold cavity when jars, pots and bottles are transformed. When the resin, still molten, meets the label, it permanently adheres to the packaging’s face.

IML is a suitable solution for packaging that passes through the cold chain, such as individual desserts, and for applications requiring indelible labeling. Currently, the in-mold label solution can be used in packaging produced using injection, blow molding or even thermoforming systems.

Unlike self-adhesive labels, IML labels are not supplied on rolls. They resemble labels applied with glue, as they are already cut to the final shape and are fed in stacks stored in a device next to the labeling station. The labels are then picked up by a robot, which inserts them at high speed into the mold cavities where the part will be formed. When it comes into contact with the molten resin, the label adheres permanently to the walls of the packaging through thermofusion. Therefore, the In-Mold Label hardly delaminates and is highly resistant to friction, humidity and contact with aggressive products—especially when printing is done on the back of the substrate.

At Valgroup, we constantly innovate to offer high-quality and efficient solutions. Our bioriented polypropylene films for in-mold labels, opaque and bi-treated, have controlled optical properties for each side, in addition to having low density, generating the “Orange Peel” effect during the injection process. The option of transparent films or even pearl film enables later printing.

Extremely versatile, BOPP for IML is widely used in the food, cosmetic, chemical, and pharmaceutical segments, in cups and buckets, and on trays, among other applications. Here at Valgroup, we are committed to sustainability and continuous innovation. We provide solutions that meet our customers’ needs and promote a more sustainable future.

Stay tuned in to the world of plastic technology, innovation and sustainability

Valgroup launches solutions focused on end-of-line automation

Continue reading

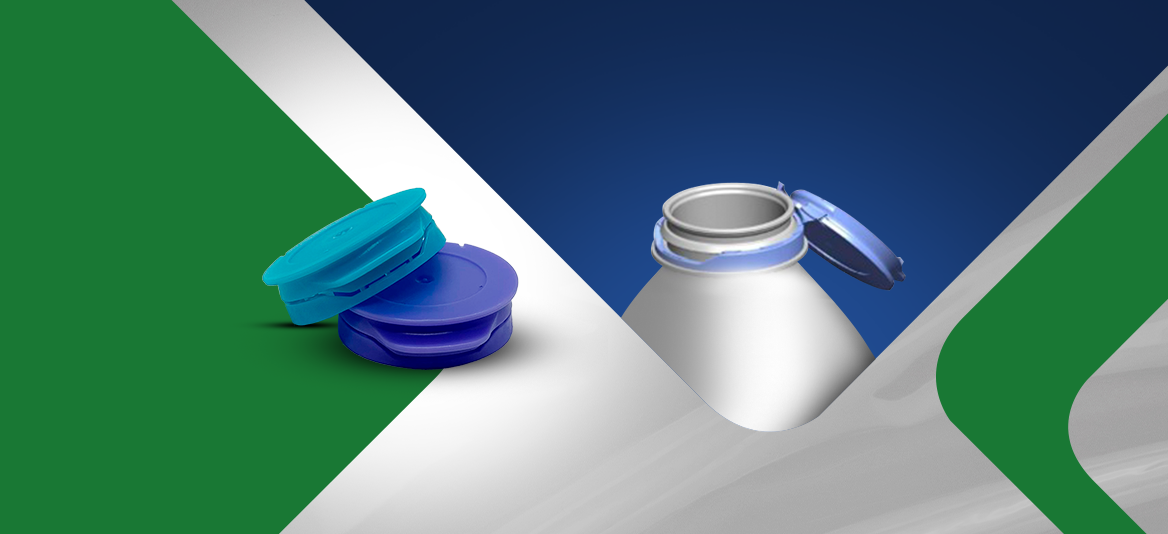

Innovation and Sustainability: Introducing Valgroup's new cap 'Snap-on Flip Top'

Continue reading

Valgroup Run 2024: Running and Solidarity with the new Valgroup Run Kids

Continue reading

The importance of shelf life for food safety and waste reduction

Continue reading

Valgroup Sustainable Innovations: Sustainability Commitment

Continue reading

Valgroup is the new supplier of Tissue packaging for Bracell

Continue reading

Comerc Energia inaugurates São João do Paracatu photovoltaic complex, and Valgroup expands its consumption of renewable power, reinforcing the commitment to sustainability

Continue reading

Valgroup launches a new Business Unit in the market dedicated to Digital Printing

Continue reading

Valgroup develops 1250ml bottles for yogurt in partnership with Serramar

Continue reading